If Electric Mirror’s success story seems a reflection of the American dream, that’s the way the Mischel family sees it too. Starting small, and sharing a vision, their dream is still unfolding even as their business has gone global.

Family, friends, dignitaries, and Marines at the ribbon cutting ceremony at Electric Mirror’s Grand Opening on May 13, 2016.

“For us, it’s always been about faith and family,” said founder and President Jim Mischel, a philosophy that hasn’t changed since he first set up shop in his family’s home in the Pacific Northwest.

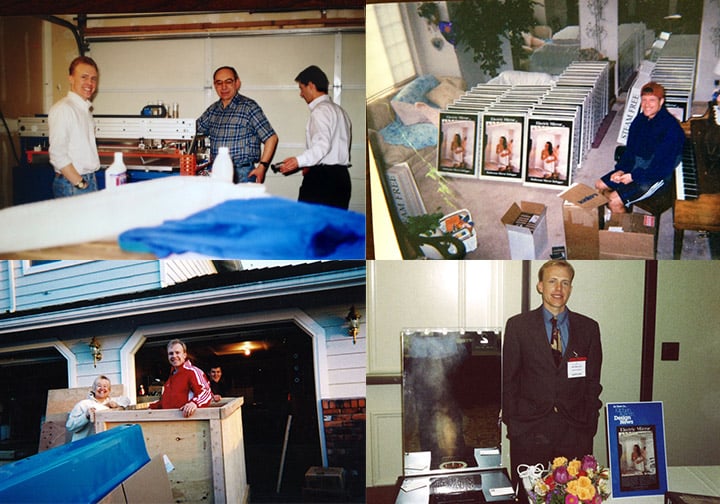

Clockwise – Jim and Doc in the shop. Aaron organizing a shipment. Faith and Jim checking out their first crate. Jim at his first trade show.

Jim Mischel Sr., or “Doc”, a former dentist with the heart of an inventor, and now Electric Mirror’s Chairman and Vice President of Research and Development, had spent many happy hours working on projects in the family’s garage. So it was only natural, he says, when he, along with his son Jim, wanted to launch his business there.

Customers flocking to Electric Mirror booth at Hotel Design Expo 2016 in Las Vegas to see our new products.

That garage, in Lynnwood, Washington, is where the Mischel family turned out their first innovation, a high-end defogging mirror. In those days, family and workforce were one and the same, with parents Faith and Doc, and younger brother Aaron handling everything from sales and phones to manufacturing. Younger sister Mia, though still in school, was also kept in the picture. It wasn’t long before stacks of orders began piling up beyond the garage, moving room to room through the house. When those stacks finally found their way into the kitchen, Faith said, she knew Electric Mirror was ready to take things to the next level.

Lighted Mirrors ready to ship around the world

Jim’s expanded production line soon included luxury lighted mirrors and makeup mirrors, an area in which he saw huge potential for upscale hotels. That foresight would later be realized in a big way, but in the beginning the hotel industry was slow to share his vision. “It took two to three years minimum before our concept caught on.”

A fantastic Eternity Lighted Mirror at the Virgin Hotel in Chicago

Technology combined with beautiful design work has distinguished Electric Mirror from the beginning, first in the hospitality industry and now with a growing commercial and residential client base. The company sells more lighted mirrors than all of their competitors combined, along with lighted makeup mirrors and mirrored medicine cabinets.

A little girl’s wonder seeing a Country Rose pattern in a Silhouette Lighted Mirror from our Cameo Designs product line

Jim, a former patent attorney, has acquired over 40 patents for cutting-edge technology specific to his products. “We’ve always been into innovative technology—first with mirror defoggers, then makeup mirrors, lighted mirrors, mirror TVs, dimming touch controls, Bluetooth® music, two-piece TVs, laser patterns, and more. It’s always been about something we wanted to do, then getting the technology to make it happen,” said Jim.

Listening to her playlist through Vive, Music in your Mirror, by Electric Mirror

With this success has come an ongoing need for more manufacturing and design space at Electric Mirror. “We went from four employees in a garage to 10 in the house, then 20 in a small facility, then made the jump to 75 and now we’re at over 380,” said Jim.

Raw 8×12 sheets of mirror glass ready for production

The company moved in December, 2015 into its current 125,000 square foot facility in Everett, Washington. Along with all the space the new facility provides came a substantial investment in new equipment that allows for faster order production, reduced environmental impact, and an increase in employee safety.

Seamless Clock in an Integrity Lighted Mirror

“Not a week goes by where we aren’t putting together some customized order for a unique product,” said Doc. He said he’s proud of Electric Mirror’s impeccable track record for standing behind each new project from start to finish. “Customers and sales reps know we’re behind them, no matter where they’re located. From the beginning, high integrity has been part of who we are, and our history shows that.”

These aren’t idle words. Electric Mirror has a large customer support field team that is ready to travel anywhere in the world, at any time, to support their clients and products.

The Electric Mirror Customer Service Team, from Left to Right: Joel Hudson – Customer Service Supervisor, Tom Cox – Customer Service Representative, Anthony Parker – Field Service Technician, Bill Schoonover – Customer Service and Warranty Manager, Fred Crumley – Customer Service Representative, Abraham Lincoln – Field Service Technician, and Eddie Nellis – Field Service Technician.

“Success in sales,” Executive VP of Sales Aaron Mischel says, “is the ability to be philosophical about rejection, and just knowing that that’s always going to be part of it.” His experience as a soccer player was a good life preparation. “If you take enough shots you will score, and if you knock on enough doors you’ll get a yes,” he said.

Residential Inside Sales Manager Travis Boyd being interviewed at the Custom Electronics Design and Installation Association (CEDIA) 2015 trade show.

The Electric Mirror sales team has grown considerably over the years. Today, over 70 sales professionals represent Electric Mirror to hospitality, commercial, healthcare, and residential designers and purchasers worldwide. The sales team joined together recently for a Global Sales Conference at Electric Mirror’s new global headquarters.

Electric Mirror Lighted Mirrors and Mirrored Cabinet on display at Studio41a residential Kitchen and Bath Showroom in Illinois.

The new facility includes a spectacular showroom of luxury products on display, something the company never had space for in the past. It’s also the manufacturing plant for Electric Mirror’s products, which serves as a positive example of cultural diversity.

Attaching hangers on mirror back, and packaging.

“We have people here from around the world, and from all walks of life,” she said, “and to us it’s like a large growing family. I always knew we would be here, and we’re not done expanding yet.”

Ladies of Electric Mirror received yellow roses from President and CEO Jim Mischel on Valentine’s Day.

Faith’s personal interest in her employees may be one reason she knows a lot more about them than what’s on their resumes, and she said it’s that personal involvement that makes Electric Mirror a very special place to work. That connection is clear as she makes her way along the production room floor, where she has a word with everyone and is ready to share a story or ask how their family is doing.

Faith Mischel surrounded by the Electric Mirror extended family.

“No matter where someone is working when they start here, I like to ask them, ‘What would you like to be doing?’” Her advice: “I tell everyone when they come here to outthink your boss,” she says. “We want that, because if you push yourself, you push us, and things come up to a whole new level.” It’s one reason, she believes, that Electric Mirror has an incredibly low turn-over rate.

Removing front protective shield after blasting lighting patterns

This commitment to caring, says Jim, is something the Mischel family actively supports through its sponsorship of non-profit organizations.

Plotting and patterns control station.

This is where Jim’s sister, Mia, brings her considerable expertise, as Vice President of Community Relations for Electric Mirror. “Through support of community outreach efforts, Electric Mirror is not only giving back,” says Mia, “but doing what we believe is our mission. We want to go the extra mile for people —that’s what we believe,” she said. Through its Compassion 25:40 corporate giving program, Electric Mirror helps local and international communities in areas such as: supporting health and wellness for people with serious diseases, providing food and shelter to orphans and widows, empowering rescue and restoration to victims of sex trafficking, and fostering stability and prosperity to those in need.

Young director working on a film project sponsored by Hollywood Heart.

It’s the final piece of what has made the American dream for the Mischel family business come true, both professionally and on a personal level.

The whole Mischel family including grand kids.

“You start with God, that comes first; then family, and then the business,” said Faith. It’s been the foundation for the Mischel family’s version of the American dream, a story that’s still far from being finished.